We are thrilled to share our work from the past year with you! You can also go and check out our Kickstarter Update for a more infor and more pictures! Our update is structured in ten chapters, each dealing with a specific topic of our activity. We start by detailing our work on the MKD System, then move on to the sensors that we use for landmine and UXO detection. Later, we offer a sneak peek into our test and demo sessions, and we talk about funding and clients. Then, we jump into our marketing activities, the events we’ve attended and awards we’ve recently received, and show our various teams throughout the last years, as well as how we reorganised our workshop area. Finally, we end the update with a few plans for the future.

Some products and prototypes, on display in our workshop

The MKD System on display at a GICHD event in Basel

1. Finalising the MKD

Just to remind you, our MKD system works as a three-step process. Step 1 – Mapping: The Destiny drone surveys and maps the land. Step 2 – Detection: The Manta drone flies over the land, detects landmines and other explosives using a multi-sensor tool and pinpoints their position on a 3D map. Step 3 – Detonation: The Manta drone flies with the chosen disposal device and destroys the detected explosives.

Both the MK Destiny (surveillance drone) and the MK Manta (detection drone) are ready for production, and this was an essential thing which we were happy to check off our ‘to do’ list. During the last couple of months, we have finished all assembly activities, and tested both the tiny parts individually and the final product as a whole. This has been a long process, as we have worked through more than 50 conceptual iterations on the computer, and over 10 mechanical versions. Now, we have assembled several Destiny and Manta drones. Speaking of assembly, we have optimised and streamlined the assembly process, and created a manufacturing booklet for each final product, which will be used for our assembly line. We learned that a single drone will take around one day to produce in our facility. However, if we get an order larger than 30 units, we will have to outsource the final assembly and packaging to one of our OEM partners. For this reason, we have already had several talks with companies in the Netherlands, as well as others from Aachen, Germany.

A major achievement was getting the Destiny certified by the Netherlands Aerospace Centre (NRL). It was a long and complex process, and we had meetings with several technical people. They opened the drone and intensively checked all cable connections, the strength of the propellers, the functioning of the software, as well as other assembly characteristics, in order to rule out the possibility of the drone falling out of the sky, for instance. Also, the drones have their own PH number, which is an identification number metallic plate for drones. When the Destiny is flying up in the air, we can contact the closest air traffic control tower, and inform them which PH number is flying around a certain area. This means that the drone will be in the international airspace radar, so that it can be safely and easily tracked. This NRL certification is European based, but can be applied to various other countries. Many companies that produce drones do not own this type of certification for their products, so having NRL certification and PH numbers is a unique selling point for the MKD System, which offers us a significant advantage.

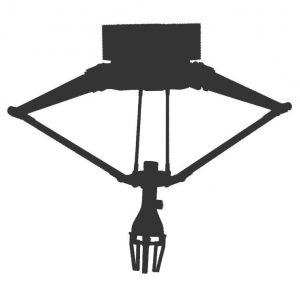

Also, for both the drones and the robotic add-ons, we have designed custom-made PCBs. These are used for the connection of the drone arms in order to make them more modular for easier transportation, for the smart battery management system, as well for the robotic central system, which is connected to the main platform. Robotic add-ons are a key component of our system, and we have developed three of them: the Rope Robot, the Delta Robot and the Gripper Robot. These robots are easily attachable on the drones: the Rope Robot and Delta Robot are used to carry multi-sensor attachments, while different types of the Gripper Robot can be deployed for carrying out precision work. These components have been in development for a while, and in the last couple of months we optimised and improved them. For instance, the Rope Robot is currently much lighter than before, because now it uses power from the drone’s battery, and no longer has its own power source. Also, it now has three significantly more powerful engines than the previous four weaker engines. Just like with the drones, we made assembly books for all these items. This means that when we send the data of the files together with an assembly book to a manufacturing company, they can manufacture the product.

2. Sensors and software

For the second step of our MKD system, detection, we need sensors which can detect landmines and other types of UXOs. Most of our OEM partners are from Germany and Sweden, and they develop multiple types of top-quality sensors that have excellent detection techniques. As a result, we decided to develop these sensors with them, and we placed together a number of different sensors into a custom-made MK Multi-Sensor.

First of all, we need to be able to detect metallic objects above the ground, such as hand grenades, UXOs and landmines, and also go below the ground with detection of metallic objects. We also aim to detect non-metallic objects, with a size ranging from around 10 cm to 2 m, but only below the ground, not above. Currently, a Manta drone flies 1 metre above the ground at a speed of 7-10 km/h equipped with the MK Multi-Sensor, and it can penetrate the ground up to 3 metres. We have collected a lot of data through multiple test sessions, some of which are available to view on our website.

Combining different sensors is something that we decided to work on, since it allows us to increase the reliability of our work through cross-checking different readings. As a result, we combine the data and readings from the multiple components of the MK Multi-Sensor, and stitch it together. For that, we are using an AI software that is made specifically for analysing sensor data, and stitching it automatically. This way, the various data collected will be analysed by the AI, leading to better results and presenting them in a way that end-users can easily understand.

3. Testing and demos

In the past, we have performed demonstrations of our products in front of several delegations from the MENA (Middle East and North Africa) region. In the meantime, we have improved our products and fine-tuned our system, and performed many internal testing sessions of different processes: manufacturing and assembly, calibration with frequencies, flight and detection. As mentioned in the previous point, in the coming months we aim to hold several demonstrations and trials in MENA countries, following which we hope to make the first deliveries. Once we have performed our beta tests, we will have a success story. Also, we will collect a lot of data, and then we can share it with interested end-users. This will make it much easier for us to show them the results of our disruptive solution.

The MK crew testing one of our drones

A field test day with the MK team

4. Funding

In the last update, we talked about how difficult it has been for us to keep funding our R&D process. With our airborne demining system finished, we had to start intensive test sessions, and that meant we had to co-develop sensors with our OEM partners, each costing several tens of thousands of Euros. Fortunately, we received funding from both LIOF and Limburg Makers, two regional organisations from the south of the Netherlands, both of which helped Mine Kafon stay alive. Also, we were successful in applying for a subsidy from the European Commission, namely the Horizon 2020 SME Instrument Phase 1. It was the most competitive call for projects to date, with a record 3275 projects evaluated, of which only 283 received funding. The MKD project was ranked #128 from all applications, and #6 in the security domain. Apart from financing, we also received a business coaching programme in order to help us fine-tune our strategy and increase our chances of success. Just last week, we welcomed our coach Niall McManus to the Mine Kafon office, and spent the day learning many valuable insights from his vast experience in internationalisation, sales and dealing with organisations from Africa, the Middle East and South-East Asia.

However, not all of our funding comes from subsidies and related programmes. We have also earned funds from leasing our products for exhibitions or museum galleries, as well as from giving presentations and lectures around the world. Now that we are finished with development, we will start delivering the MKD system, and we also aim to make Mine Kafon merchandise available for orders in the next couple of months. Also, we would like to announce that we intend to make investing in Mine Kafon possible in the very near future. So, in case you are interested, you can contact us at finance@minekafon.org and we can discuss about it.

5. Clients

This is a very important moment in Mine Kafon’s history, especially because we are undergoing a transition from an R&D phase to a go-to-market phase. As we mentioned before, our products are finalised, and we are ready for orders. We already collaborate with OEM partners from around the globe, and our distribution channel has been put into place. By using one software, we can order all necessary parts for the manufacturing process. This software communicates directly with our main partners, so they receive a notification whenever we place an order for equipment.

Over the past six months, we’ve been in contact with more than 50 potential interested parties, the main ones being either NGOs, governments, or resellers of demining products. Currently, we find ourselves in advanced discussions with several of these interested parties, and the first trials and demonstrations are starting in the coming few months. As these arrangements are private, we cannot yet disclose specifics about them, but we are sure that we will be successful in proving how Mine Kafon technology can help them. What we can do once these demonstrations are performed is sharing some of the data gathered in the next update.

6. Marketing

After almost exclusively having engineers and software developers around, we’ve recently expanded our team’s business department. A marketeer and a social media coordinator joined us, and they will be responsible with all marketing activities. We’re also excited to be working on several new video projects, which you will see on our YouTube channel very soon. Below, you can watch a short introductory video on the MK Manta. So, keep an eye on our social media channels and on our website to be the first ones to find out what we’re up to these days!

Also, maybe you already noticed – we updated our website. We’re no longer just an R&D lab, our products are finished and ready to be ordered, so we wanted these things to be obvious straight from minekafon.org. We also started writing a fortnightly blog, which will contain topics such as Mine Kafon updates, any events that we attend, as well as various industry trends and developments that we find interesting. We were also super excited to welcome a team from Red Bull TV in our office. They made an awesome short documentary about our company, mission and solution, which you can watch here if you’re in Austria or Germany.

7. Events and awards

In the past seven years, we have promoted our idea through a worldwide awareness campaign. Or mission and vision reached millions of people, and inspired change not only in peoples’ mindsets, but also in the methods used. Many were sceptical about our drone-based demining solution back in 2013, because drones were still a very niche market. Things have changed meanwhile, and starting with 2015 many NGOs and organisations around the world started listening to us and improving their work. We were happy to notice this shift when giving a presentation at the 7th Mine Action Technology Workshop organised by GICHD in Basel, Switzerland, in November 2019. Many NGOs, including UNMAS, DMAC and HALO Trust are open to new technologies such as robots and drones, and are happy to use them because doing so improves their work. We are proud to have pioneered this trend, and we look forward to what the future brings.

In November 2019, we were also honoured to receive the ‘Design per la vita’ prize as part of the 3rd Edition of Etico/Ethical Awards. Massoud travelled to Milan, Italy, and attended the event held at the Palazzo Reale in order to accept the award. Last, but not least, we attended the Amsterdam Drone Week event in December 2019 with our entire team. We loved seeing the newest designs in terms of drones, and networked with many world-changers.

We’re focussing on our MKD system nowadays, but let’s not forget about the Mine Kafon Ball! We always love seeing it among other inspiring artworks, and it’s certainly in good company in the Museum of Modern Art (MoMA) in New York. And since we are preparing for trials of the MKD System in multiple regions, including the Hassani brothers’ native Afghanistan, we have been meeting with officials in preparation for our project, in order to make sure that everything goes smooth.

NGOs, demining organisations and private companies listening to Mine Kafon’s presentation in Basel

Massoud’s presentation about the MKD System at a GICHD event in Basel, Switzerland

8. Team

Over the past couple of years, we’ve worked with over 85 different people from all over the world. We loved having each and every one of them here – they’ve taught us a lot, and made sure we never ran out of positive energy. The biggest problem has been that most of these talented ladies and gentlemen were only here temporarily. Our ideal scenario, which we are working towards, is having a fixed team of 5-6 people, alongside a handful of interns, trainees and volunteers.

9. Workspace

Having a clearly structured and organised workspace leads to more efficient results, so we have been continuously improving our working environment. We placed new tables and furniture in the working area, and now everything is clinically arranged. We obtained new soldering stations, anti-static mats, new storage compartments and new wall displays used for hanging and storing components. We purchased a wide variety of tools in order to get the best working results on our prototypes, and arranged everything within boxes that have been labelled. We keep the whole parts in stock, so that every drone as its own neatly structured department. This way, we can track all the components and electronics that every drone needs via storage box numbers.

As for the mechanical engineering corner, we acquired three additional 3D printers and one SLS printer last year, as well as other tools such as laser cutters and sanding machines in order to give our designs a final look. A week before Christmas, we took an entire day in order to rearrange our workspace, move the furniture around and have a stand where we now proudly display our finished drone prototypes. Last, but not least, we bought a company van, so now it’s really easy and cheap for us to go around Europe for presentations, lectures, exhibitions or even nearby demonstrations.

10. Next steps

Resolutions for 2020? We have quite a few! As we mentioned before, our top objective for the upcoming months is having a couple of successful demonstrations with our most promising connections, and following this with the first few deliveries. We want to get feedback from these user test scenarios, and share this data. We’re also looking at obtaining additional international and/or local certification, and offering custom-designed drone pilot courses. Last, but not least, we want to optimise our distribution channels, and work on aspects such as after-sales and warranties. It will be a busy year, but we’re aiming for a brighter future, so we wouldn’t have it any other way!

Meanwhile, you can find us on LinkedIn and Instagram, where we post updates several times per week. We’re also active on Facebook and Twitter, so do check us out!

Soldering wires in the MK workshop

Finishing assembly of the MK Destiny

All the best,

The Mine Kafon Team

Long time supporter, and thought I’d drop a comment.

Your organization’s wordpress site is very

sleek – hope you don’t mind me asking what theme you’re using?

(and don’t mind if I steal it? :P)

I just launched my small businesses site –also built in wordpress

like yours– but the theme slows (!) the site down quite

a bit.

In case you have a minute, you can find it by searching for “royal cbd” on Google (would appreciate any feedback) – it’s still

in the works.

Keep up the good work– and hope you all take care of yourself during the coronavirus scare!

~Justin